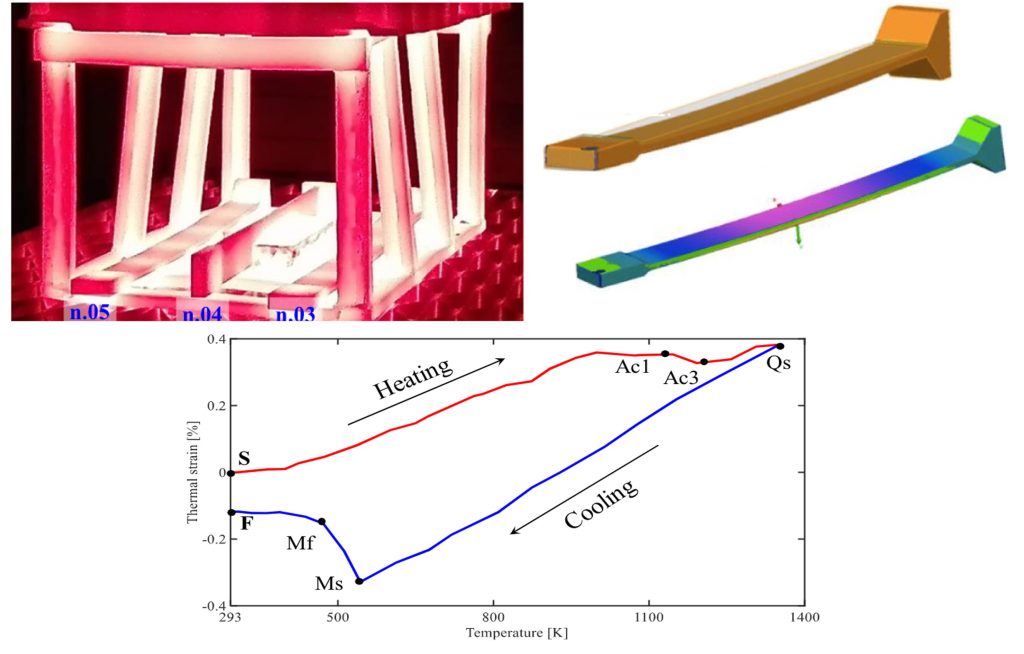

To improve their mechanical properties, metal components are often subjected to heat treatments, whose main drawback is represented by the appearance of undesired geometric distortion and residual stresses. In the case of quenching (oil or water) of steel mechanical elements, the above-mentioned phenomenon is mainly related to the high thermal gradient that occurs during the fast-cooling process. A strong thermal expansion mismatch is produced among the surface, that cools down quickly becoming instantly martensite, and the untransformed austenite hot-core, that turns later into martensite. Mechanical components operating at high temperatures (e.g. turbine blades), are generally made of high temperature creep resisting steel. In order to obtain better mechanical properties, these materials undergo a solubilization heat treatment. In this work, the distortion failure of mechanical components made of high temperature creep resisting steel undergoing a heat treatment is dealt with. Beam-like samples were measured with a laser scanner system, before and after a solubilization (air quenching) heat treatment to evaluate its permanent deflection. A numerical model, based on the Finite Element method, was then developed. Comparing numerical results with experiments, it has been observed that, with respect to the case of water quenching, where the distortion is mainly related to phase transformation strains and TRIP (Transformation Induced Plasticity), in the considered case the failure seems to be mainly affected by a low-stress diffusional creep due to the proper weight, when the component is held at high temperature.

F. De Bona, J. S. Novak, A. Lanzutti, G. Lucacci. Distortion after solubilization treatment of X12CrNiMoV12-3 beam-like samples: A novel FE modelling technique supported by experiments. (2022) Engineering Failure Analysis.